Understanding the Basics of Magnetic Roller Separators

2024-10-25

Magnetic roller separators are essential machines in industries that deal with bulk materials. They efficiently separate ferrous particles from non-ferrous materials, offering a cost-effective and environmentally friendly solution for recycling and waste management processes. Whether you are in the mining, food, or manufacturing industry, understanding how these machines work can optimize your production process and improve product purity.

What is a Magnetic Roller Separator?

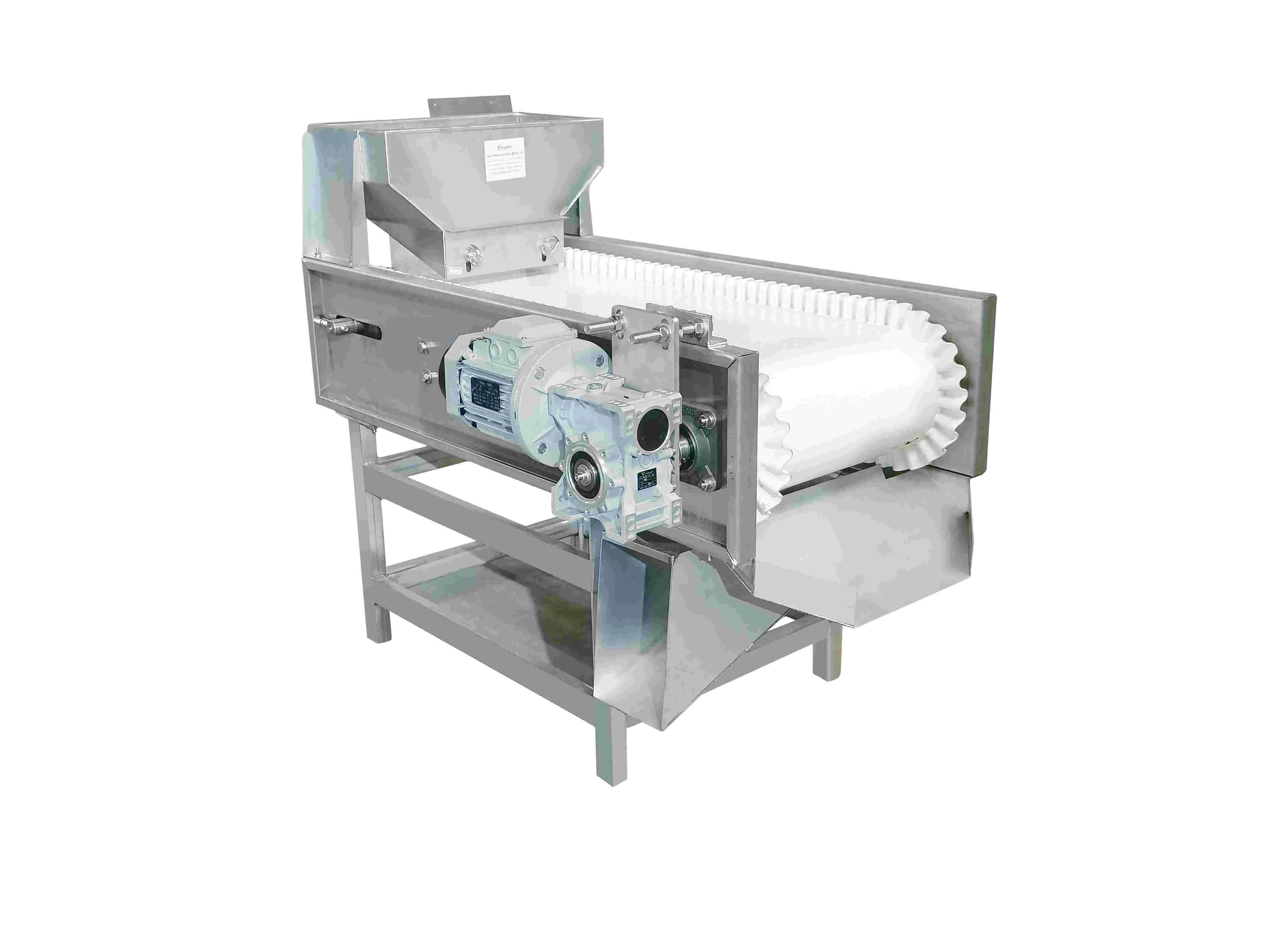

A magnetic roller separator is a type of magnetic separator that uses powerful magnetic fields to separate magnetic materials from non-magnetic ones. The heart of the device is a cylindrical drum that rotates while a magnetic field is applied across its surface. When bulk material passes through, ferrous particles (such as iron) are attracted to the magnetic drum, while non-magnetic materials fall away, continuing their flow through the production process.

How Do Magnetic Roller Separators Work?

The working principle of magnetic roller separators is straightforward:

1. Material Feed: Bulk material is fed onto a conveyor belt that transports it to the magnetic drum.

2. Magnetic Separation: As the material moves toward the drum, the magnetic field pulls the ferrous particles towards the surface of the drum.

3. Rotation: The drum rotates, carrying the ferrous particles with it.

4. Separation Point: As the drum continues to rotate, the magnetic particles are carried past a certain point where they drop into a separate collection bin, while non-magnetic materials fall off earlier and continue on a different path.

Types of Magnetic Roller Separators

1. Single Roller Separator: Ideal for smaller applications where only one stage of separation is needed.

2. Double Roller Separator: Provides an additional level of separation for more complex materials or higher levels of ferrous contamination.

3. Multistage Roller Separator: For industries requiring extremely high levels of purity, multistage separators can remove even trace amounts of ferrous particles.

Applications of Magnetic Roller Separators

- Recycling: Separating ferrous metals from plastic, rubber, or glass waste.

- Mining: Removing iron ore from non-magnetic minerals.

- Food Processing: Ensuring metal contaminants are removed from grain, sugar, and other consumable goods.

- Pharmaceuticals: Ensuring purity by removing metal particles from powdered drugs.

Benefits of Using Magnetic Roller Separators

- Increased Efficiency: They allow for continuous operation without the need for frequent stops for manual separation.

- Cost-Effective: The reduction in labor costs and waste leads to long-term savings.

- Improved Product Quality: By removing metal contaminants, they improve the purity of the final product.

- Environmentally Friendly: Reducing waste materials and encouraging recycling initiatives.

Magnetic roller separators are critical in various industries for their ability to efficiently remove ferrous materials. By understanding the principles behind their operation and their many applications, businesses can leverage these machines to improve both productivity and product quality.