Understanding Excavator Carrier Rollers: A Key Component for Smooth Operations

2024-09-10

When it comes to the heavy-duty operations of an excavator, the undercarriage is one of the most critical areas for ensuring the machine’s reliability and efficiency. Among the many parts of the undercarriage, the carrier roller plays a pivotal role in maintaining the machine’s stability, smoothness, and durability. But what exactly is an excavator carrier roller, and why is it so important to the machine’s overall performance?

In this blog, we will explore the function of an excavator carrier roller, its components, and the impact it has on the performance and longevity of an excavator.

What is an Excavator Carrier Roller?

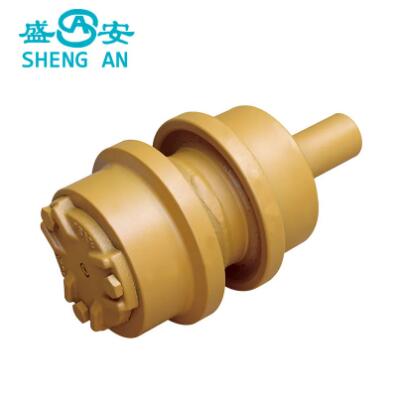

The carrier roller, also known as the top roller, is a small but crucial part of the undercarriage system of an excavator. Located at the top of the undercarriage, its primary function is to support the upper section of the excavator's track as it loops over the frame of the machine. By helping guide the track and distributing the load evenly across the undercarriage, the carrier roller ensures smoother movement and better weight distribution during operation.

Unlike the bottom rollers, which bear the weight of the machine and help the excavator travel, the carrier roller prevents the track from sagging between the sprocket and the idler, improving the overall alignment of the tracks.

Key Components of an Excavator Carrier Roller

A typical excavator carrier roller consists of the following components:

1. Roller Body: The main cylindrical part that comes in contact with the excavator’s track.

2. Shaft or Axle: The shaft runs through the center of the roller and allows it to rotate smoothly.

3. Seals and Bearings: These components reduce friction, provide smooth motion, and keep debris like dirt and water from entering the roller.

4. Mounting Bracket: This bracket connects the roller to the excavator’s frame, keeping it securely in place.

Why Are Carrier Rollers Important?

Though carrier rollers may seem like small components, they are crucial for the following reasons:

1. Track Alignment: The roller prevents the track from sagging, which maintains proper alignment and prevents uneven wear.

2. Smooth Operation: With a properly functioning carrier roller, the excavator can move smoothly and efficiently, which is essential when working on uneven terrain or performing heavy-duty tasks.

3. Reduced Wear on Tracks: By keeping the tracks aligned and properly tensioned, carrier rollers help reduce wear and tear on both the tracks and the entire undercarriage system, extending their lifespan.

4. Improved Operator Comfort: A well-maintained undercarriage, including high-quality carrier rollers, leads to less vibration and a smoother ride, improving operator comfort and productivity.

Types of Carrier Rollers

Carrier rollers come in different sizes and designs depending on the type and size of the excavator. Generally, there are two main types:

1. Single Flange Carrier Rollers: These rollers are designed for smaller excavators and are used on machines that typically operate on more level terrain.

2. Double Flange Carrier Rollers: Used on larger and heavier excavators, double flange rollers provide additional stability and support when working on rougher or more uneven terrain.

Both types of rollers are built to withstand harsh conditions and are constructed from hardened steel to handle heavy loads and resist impact.

Maintenance of Carrier Rollers

Maintaining the carrier rollers is essential for ensuring the longevity of your excavator. Poorly maintained rollers can lead to:

- Misaligned tracks

- Increased wear on the undercarriage

- Reduced performance and fuel efficiency

Here are a few maintenance tips:

- Regular Inspections: Inspect the rollers frequently for any signs of wear, damage, or misalignment.

- Lubrication: Make sure the seals and bearings are properly lubricated to prevent friction and premature wear.

- Replace Damaged Rollers: Any damaged or worn-out carrier rollers should be replaced promptly to avoid further issues with the tracks or undercarriage.

Conclusion

Carrier rollers are an integral part of the excavator’s undercarriage system, ensuring that the tracks remain properly aligned and function smoothly. By distributing the weight and preventing track sagging, carrier rollers enhance the overall performance and longevity of the machine. Regular maintenance and timely replacements of worn-out rollers are essential to keep your excavator running smoothly and efficiently, reducing downtime and maximizing productivity.