Revolutionizing Manufacturing: The Advantages of Intelligent Factory Supply Automated Edge Banding Cells

2024-03-15

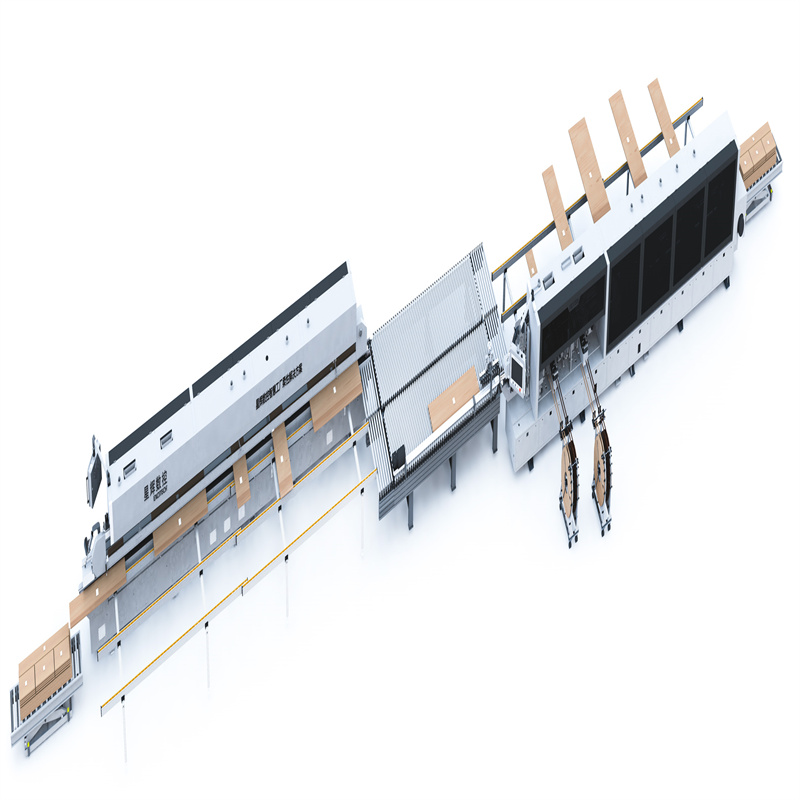

In the ever-evolving landscape of manufacturing, innovation continues to drive progress, transforming traditional processes and revolutionizing production workflows. One such innovation that has reshaped the woodworking and furniture manufacturing industry is the Intelligent Factory Supply Automated Edge Banding Cell. This advanced technology offers a host of advantages over traditional manual processes, paving the way for increased efficiency, precision, and productivity. In this blog, we'll explore the key advantages of using an intelligent factory supply automated edge banding cell compared to traditional manual processes.

1. Enhanced Efficiency:

One of the most significant advantages of intelligent factory supply automated edge banding cells is their ability to significantly enhance efficiency. Unlike manual processes, which rely on labor-intensive tasks and are susceptible to human error and variability, automated edge banding cells operate with precision and consistency. Automated material handling, edge banding application, trimming, and finishing processes streamline workflows, reduce cycle times, and maximize throughput, resulting in higher productivity and reduced lead times.

2. Improved Precision and Consistency:

Precision is crucial in edge banding operations to ensure a seamless and high-quality finish. Intelligent factory supply automated edge banding cells excel in this aspect, leveraging advanced technology such as vision systems, robotics, and CNC machining to achieve precise and consistent results. Automated processes eliminate the variability inherent in manual operations, minimizing errors, defects, and rework. The result is a higher level of quality and craftsmanship in the finished products, enhancing customer satisfaction and brand reputation.

3. Minimized Labor Costs:

Manual edge banding processes require a significant investment in labor, as skilled workers are needed to perform tasks such as material handling, edge banding application, trimming, and finishing. In contrast, intelligent factory supply automated edge banding cells reduce the reliance on manual labor by automating these tasks. This not only reduces labor costs but also frees up skilled workers to focus on higher-value activities, such as design, engineering, and quality control, ultimately improving overall operational efficiency and resource utilization.

4. Increased Safety:

The safety of workers is a top priority in any manufacturing environment. Traditional manual edge banding processes pose inherent risks, including exposure to sharp tools, repetitive strain injuries, and accidents associated with material handling. Intelligent factory supply automated edge banding cells mitigate these risks by minimizing manual intervention and automating hazardous tasks. Workers are protected from potential injuries, while the risk of workplace accidents is significantly reduced, creating a safer and more conducive working environment.

5. Scalability and Flexibility:

Intelligent factory supply automated edge banding cells offer scalability and flexibility to adapt to changing production demands and requirements. Unlike traditional manual processes, which may be limited by the availability of skilled labor and physical space constraints, automated systems can be easily scaled up or down to accommodate fluctuations in production volume. Additionally, modular designs and customizable configurations allow for versatility in production setups, enabling manufacturers to efficiently handle a diverse range of products and specifications.

6. Data-driven Decision Making:

Automation in edge banding cells enables real-time data collection and analysis, providing valuable insights into production performance, efficiency, and quality metrics. Manufacturers can leverage this data to identify areas for improvement, optimize processes, and make informed decisions to drive continuous improvement initiatives. By harnessing the power of data-driven decision-making, manufacturers can enhance operational efficiency, minimize waste, and maximize profitability over time.

In conclusion, the advantages of using intelligent factory supply automated edge banding cells compared to traditional manual processes are undeniable. From enhanced efficiency and precision to minimized labor costs and increased safety, these innovative systems offer a transformative solution for modern manufacturing challenges. By embracing automation and leveraging advanced technology, manufacturers can unlock new levels of productivity, quality, and competitiveness, positioning themselves for success in today's fast-paced and dynamic market landscape.