Precision Perfected: Unveiling the Laser-Cut Precision in Die Making

2023-11-30

Introduction:

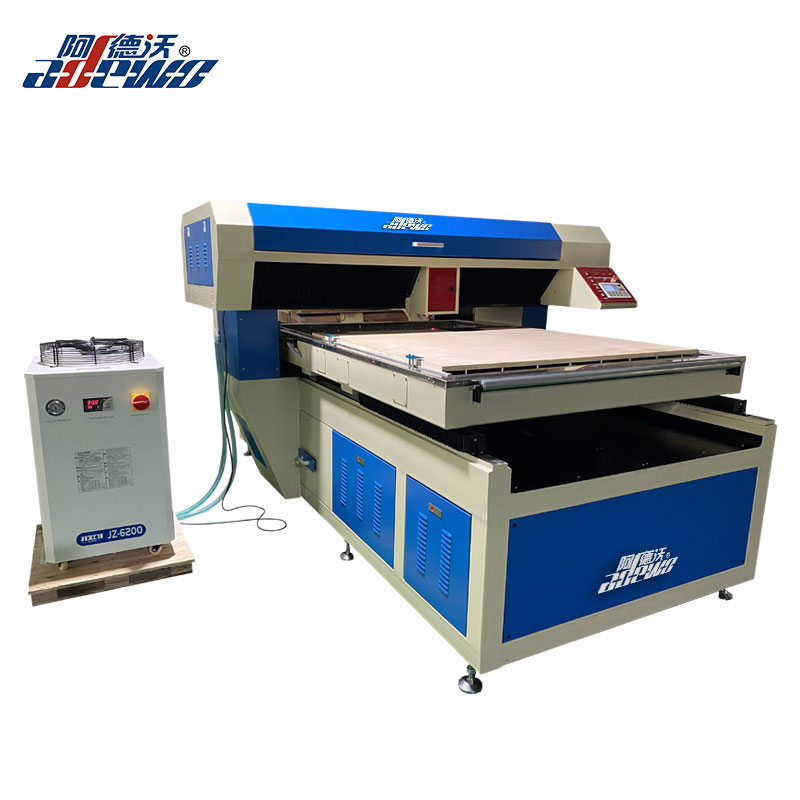

In the world of die making, precision is not just a goal – it's a necessity. The marriage of technology and craftsmanship is nowhere more apparent than in our cutting-edge Laser Cutting Machine designed explicitly for die making. In this blog, we delve into the precision and accuracy capabilities that set our machine apart, shaping the future of precision engineering in the realm of die production.

1. Unparalleled Precision:

Our Laser Cutting Machine epitomizes precision, navigating the intricate details of die designs with unmatched accuracy. Utilizing advanced laser technology, it ensures that each cut is executed with surgical precision, meeting the stringent standards demanded by modern industries.

2. Microscopic Detailing:

Die making often requires working with intricate patterns and fine details. Our laser cutting machine excels in reproducing microscopic detailing, capturing the essence of the design with meticulous accuracy. Every curve, contour, and edge is rendered faithfully, allowing for the creation of dies that stand out in their precision.

3. Consistency Across Materials:

Different materials pose different challenges, but our Laser Cutting Machine rises to the occasion. Whether cutting through metals, plastics, or composites, the machine maintains a consistent level of precision across materials. This adaptability ensures that the quality of die production remains unwavering, regardless of the material at hand.

4. Tight Tolerances, Minimal Deviations:

Meeting tight tolerances is a hallmark of our Laser Cutting Machine. The digital precision control allows for cuts within razor-thin tolerances, minimizing deviations and ensuring that each die produced aligns seamlessly with the intended specifications. This level of accuracy eliminates costly errors and rework, streamlining the die-making process.

5. Reduced Kerf Width:

Kerf width, the material removed during cutting, is a critical factor in precision. Our machine boasts a reduced kerf width, optimizing the use of material and further enhancing precision. This not only contributes to cost efficiency but also aligns with sustainable manufacturing practices.

6. Digital Intelligence for Accuracy:

The intelligence embedded in our Laser Cutting Machine is digital precision personified. The machine's digital control allows for accurate replication of designs, ensuring that each die is a faithful representation of the digital blueprint. This digital intelligence eliminates the variability associated with manual processes, setting a new standard for accuracy in die making.

7. Real-time Monitoring and Corrections:

To maintain precision throughout the cutting process, our Laser Cutting Machine incorporates real-time monitoring capabilities. Any deviations are detected promptly, and the machine makes instantaneous corrections, guaranteeing that the final product meets the exacting standards set by die makers and industries alike.

Conclusion:

In the realm of die making, precision is not just a feature – it's the essence of our Laser Cutting Machine. As technology and craftsmanship converge, our commitment to delivering unparalleled precision and accuracy remains unwavering. With microscopic detailing, consistent performance across materials, and real-time monitoring, our Laser Cutting Machine paves the way for a new era in precision engineering, redefining what's possible in the world of die production.