Key Maintenance Practices to Ensure the Longevity of a Metalworking Bronze Sintering Grinding Wheel

2024-07-04

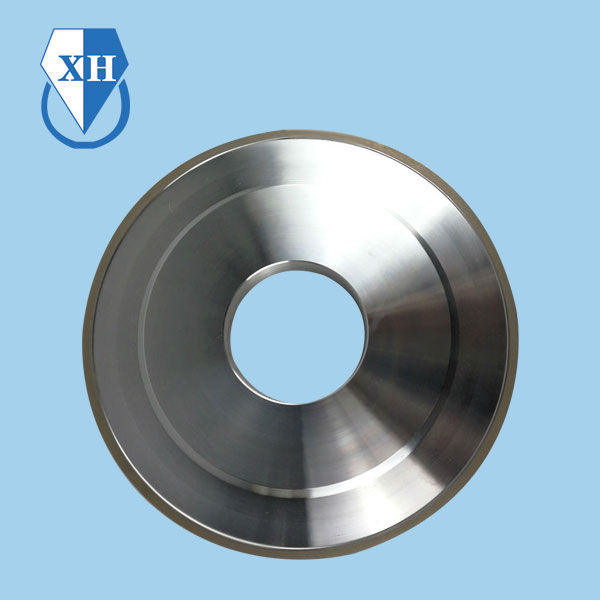

Metalworking bronze sintering grinding wheels are known for their durability, precision, and efficiency in various industrial applications. However, to maximize their lifespan and maintain their performance, proper maintenance practices are essential. This blog will outline the key maintenance practices required to ensure the longevity of a metalworking bronze sintering grinding wheel.

1. Regular Cleaning

Keeping the grinding wheel clean is crucial for maintaining its effectiveness and longevity. Over time, metal shavings, dust, and other debris can accumulate on the wheel's surface, leading to clogging and reduced grinding efficiency. Regularly cleaning the wheel with a soft brush or compressed air helps remove these contaminants, ensuring that the abrasive surface remains exposed and effective.

2. Proper Storage

Proper storage is vital to prevent damage to the grinding wheel when it is not in use. Store the wheels in a dry, cool environment away from direct sunlight and moisture, as these factors can cause the wheel to degrade or become brittle. Additionally, avoid stacking grinding wheels directly on top of each other to prevent chipping or cracking. Instead, store them in a vertical position or on a flat surface with proper support.

3. Regular Inspection

Regular inspection of the grinding wheel is essential to identify any signs of wear, damage, or imbalance. Before each use, visually inspect the wheel for cracks, chips, or uneven wear. If any damage is detected, replace the wheel immediately to prevent accidents and ensure optimal performance. Periodic inspections can also help identify issues early, allowing for timely maintenance and replacement.

4. Dressing the Wheel

Dressing the grinding wheel is a maintenance practice that helps restore its sharpness and correct any imbalance. Dressing involves removing a small amount of material from the wheel's surface to expose fresh abrasive grains and maintain the wheel's shape. Use a diamond dresser or dressing stick to perform this task regularly, especially if the wheel shows signs of glazing or uneven wear. Proper dressing ensures that the wheel grinds efficiently and produces a consistent finish.

5. Balancing the Wheel

An imbalanced grinding wheel can cause vibrations, reduce grinding accuracy, and increase wear on the machine's bearings. Regularly check and balance the grinding wheel to ensure smooth and stable operation. Use a balancing stand or a balancing arbor to achieve this. Properly balanced wheels not only improve grinding performance but also extend the lifespan of both the wheel and the grinding machine.

6. Monitoring Operating Conditions

Monitoring the operating conditions of the grinding wheel is crucial for maintaining its longevity. Ensure that the wheel operates within the recommended speed range specified by the manufacturer. Exceeding the maximum operating speed can lead to wheel breakage and accidents. Additionally, avoid excessive pressure during grinding, as this can cause the wheel to overheat and degrade more quickly.

Conclusion

Ensuring the longevity of a metalworking bronze sintering grinding wheel requires consistent and diligent maintenance practices. Regular cleaning, proper storage, routine inspection, dressing, balancing, monitoring operating conditions, coolant management, and careful handling are all critical steps in maintaining the wheel's performance and extending its lifespan. By implementing these key maintenance practices, industries can achieve more efficient and cost-effective grinding operations, ultimately enhancing productivity and product quality.