Crafting Sustainability: How the Production Process of Handmade White Porcelain Minimizes Environmental Footprint

2024-06-28

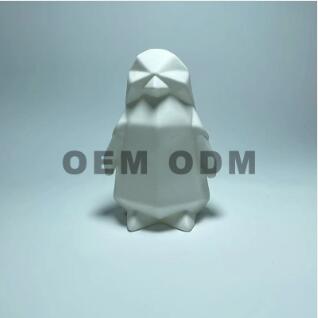

Handmade white porcelain stands out not only for its exquisite beauty and craftsmanship but also for its sustainable production practices. Unlike mass-produced ceramics, the production of handmade white porcelain prioritizes eco-friendly methods that minimize environmental impact. In this blog, we delve into how the production process of handmade white porcelain reduces its environmental footprint compared to other types of ceramics, highlighting its role in sustainable artistry.

1. Use of Natural and Renewable Resources

The production of handmade white porcelain begins with the use of natural and renewable resources, primarily high-quality clay. This clay is sourced sustainably, often from local deposits that minimize transportation and extraction impacts. By utilizing natural materials, the production process reduces reliance on non-renewable resources and lowers its environmental footprint from the outset.

2. Energy-Efficient Kiln Firing

Handmade white porcelain is fired in kilns that are designed to be energy-efficient. Artisans carefully control the firing process to achieve the desired strength, translucency, and aesthetic qualities of the porcelain while minimizing energy consumption. Modern kilns may utilize advanced technologies such as heat recovery systems and precise temperature controls, further optimizing energy efficiency.

3. Minimal Chemical Additives

Unlike some mass-produced ceramics that rely on synthetic additives and glazes containing harmful chemicals, the production of handmade white porcelain typically involves minimal chemical additives. Artisans prioritize natural ingredients and non-toxic glazes, ensuring that the finished pieces are safe for both consumers and the environment. This reduces emissions of volatile organic compounds (VOCs) and minimizes pollution during production.

4. Handcrafted Artistry and Local Labor

Handmade white porcelain is crafted using traditional techniques and artisanal skills that have been passed down through generations. The production process often involves skilled labor and craftsmanship, supporting local economies and communities. By employing local artisans and preserving traditional methods, handmade porcelain contributes to sustainable livelihoods and cultural heritage preservation.

5. Reduction of Waste and Resource Efficiency

Artisans producing handmade white porcelain prioritize resource efficiency and waste reduction throughout the production process. Clay scraps and unused materials can be recycled or repurposed, minimizing waste generation. Additionally, meticulous craftsmanship ensures that each piece is crafted with precision, reducing the need for rework and optimizing material use.

6. Longevity and Durability

Handmade white porcelain is known for its durability and longevity, with well-crafted pieces often lasting for generations. This extended lifespan reduces the need for frequent replacements and minimizes the environmental impact associated with manufacturing new products. The longevity of handmade porcelain supports sustainable consumption practices by promoting products that are built to last.

Conclusion

The production of handmade white porcelain exemplifies sustainable artistry through its use of natural resources, energy-efficient practices, minimal chemical additives, and support for local craftsmanship. Compared to mass-produced ceramics, handmade porcelain minimizes its environmental footprint by prioritizing eco-friendly production methods and promoting sustainable consumption.

Choosing handmade white porcelain not only enhances your living space with its beauty and craftsmanship but also aligns with principles of environmental stewardship and sustainable living. Each piece tells a story of tradition, artistry, and responsible manufacturing practices, making handmade white porcelain a meaningful choice for environmentally conscious consumers and collectors alike.