What kind of training is required to operate and maintain the Auto Close Cabinet Door Vacuum Membrane Press Machine effectively

2023-10-20

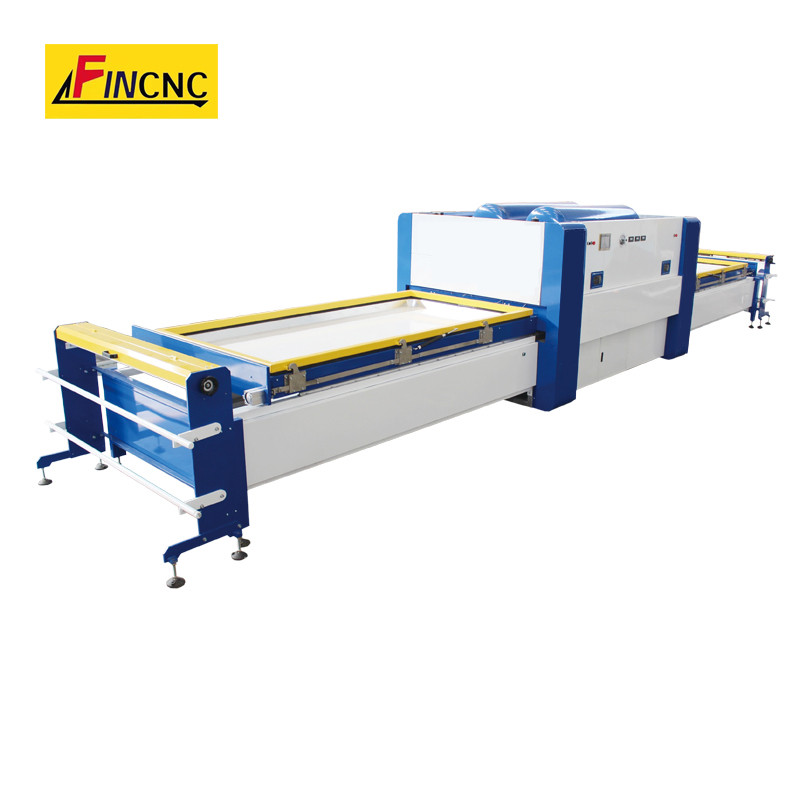

To operate and maintain an Auto Close Cabinet Door Vacuum Membrane Press Machine effectively, operators and maintenance personnel should undergo specific training. This training ensures safe and efficient operation, as well as the longevity of the machine. Here are the key training components required:

Machine Operation Training:

1. Safety Procedures: Operators must be trained in safety protocols, including the use of personal protective equipment (PPE) and emergency procedures such as using the emergency stop button.

2. Machine Familiarization: Trainees should become familiar with the machine's components, controls, and features. This includes understanding the functions of heating elements, vacuum systems, and the control panel.

3. Material Handling: Proper handling and preparation of the materials to be laminated are critical. Operators should learn how to load and position materials correctly.

4. Operating Procedures: Detailed instruction on starting, stopping, and adjusting the machine should be provided. This includes setting the appropriate temperature, pressure, and vacuum levels.

5. Monitoring and Quality Control: Operators should be trained to monitor the lamination process for any irregularities, ensuring a high-quality finish. They should also know how to make adjustments if necessary.

6. Maintenance Awareness: Operators should be aware of basic maintenance tasks, such as cleaning and daily inspections, to ensure the machine's proper functioning.

Maintenance Training:

1. Maintenance Schedule: Train maintenance personnel to follow a maintenance schedule, as recommended by the manufacturer. This includes regular cleaning, inspection, and component replacement.

2. Specific Maintenance Tasks: Maintenance personnel should receive training on specific maintenance tasks, such as cleaning the worktable, inspecting the vacuum system, and checking the heating elements.

3. Troubleshooting: Training should cover common issues that may arise during operation and how to troubleshoot and address them effectively.

4. Safety during Maintenance: Emphasize the importance of safety during maintenance activities, such as locking out the machine to prevent accidental start-up and using appropriate safety equipment.

Record Keeping:

Training should include guidance on maintaining detailed records of all maintenance activities, including dates, tasks performed, and any issues identified. Proper record-keeping is crucial for tracking the machine's history and ensuring compliance with maintenance schedules.

Emergency Procedures:

Operators and maintenance personnel should be trained on emergency procedures, including how to respond to equipment malfunctions, electrical issues, or any other unexpected situations.

Ongoing Education:

As technology and machinery evolve, ongoing education is important. Keep operators and maintenance personnel updated on new features, technologies, and best practices related to the Auto Close Cabinet Door Vacuum Membrane Press Machine.

Manufacturer's Guidelines:

Always follow the manufacturer's guidelines and recommendations for training. Many manufacturers offer training programs, manuals, and support services to ensure the effective and safe operation of their equipment.

Proper training is essential for the safe and efficient use of the Auto Close Cabinet Door Vacuum Membrane Press Machine. It helps reduce the risk of accidents, ensures consistent product quality, and extends the machine's lifespan.